Automatic upper plane labeling machine for lat surface objects

1. With PLC & touch screen system, fast & stable, suitable for longtime work

2. The I/O self-check function, can display all system photoelectric signals & motor, shorten repair time, reduce maintenance cost.

3. With stepless speed control, labeling speed automatically changes according to conveying speed, no need to move labeling sensor.

4. Objects positioning system can be equipped for special shapes, in order to get accurate labeling effect.

5. Made of SUS304 & alumni alloy, totally meeting GMP requirements.

DESCRIPTION

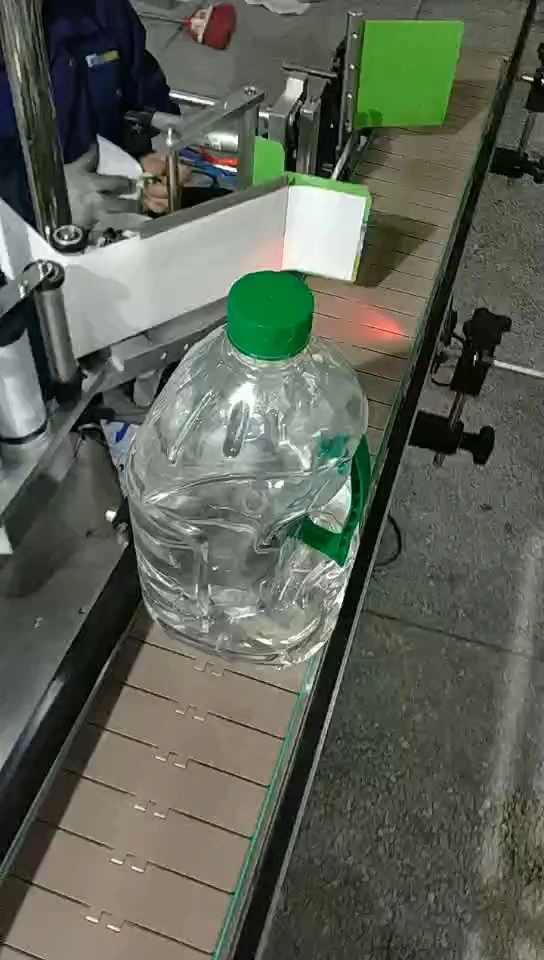

This upper plane labeling machine is suitable for various top plane labeling of objects or bottles with flat or slightly arched surface, like cartons, cardboard, boxes, round bottles top cap labeling

MAIN FEATURES

1. With PLC & touch screen system, fast & stable, suitable for longtime work

2. The I/O self-check function, can display all system photoelectric signals & motor, shorten repair time, reduce maintenance cost.

3. With stepless speed control, labeling speed automatically changes according to conveying speed, no need to move labeling sensor.

4. Objects positioning system can be equipped for special shapes, in order to get accurate labeling effect.

5. Made of SUS304 & alumni alloy, totally meeting GMP requirements.

MAIN PARAMETERS: (CUSTOMIZED)

| Model | GZAL-P130 | |

| Label height | Max 130mm | |

| Label roll size | Inner diameterφ76 mm, Outer diameter Max φ350mm | |

| Suitable products | Objects with flat or slightly arched surface, like cartons, cardboard, boxes, round bottles top cap labeling | |

| Capacity | 30-120pcs/min (depends on object & label size; 0-25m/min) | |

| Labeling Precision | ±1mm | |

| Voltage | AC 220V,50/60Hz. 0.8KW | |

| G.W. | 280Kg | |

| Dimension | L1500 mm*W1100 mm*H1400 mm | |