Come produttore professionale di apparecchiature di riempimento in Cina. GLZON è specializzata nella creazione di sistemi di riempimento di liquidi da oltre 22 anni.

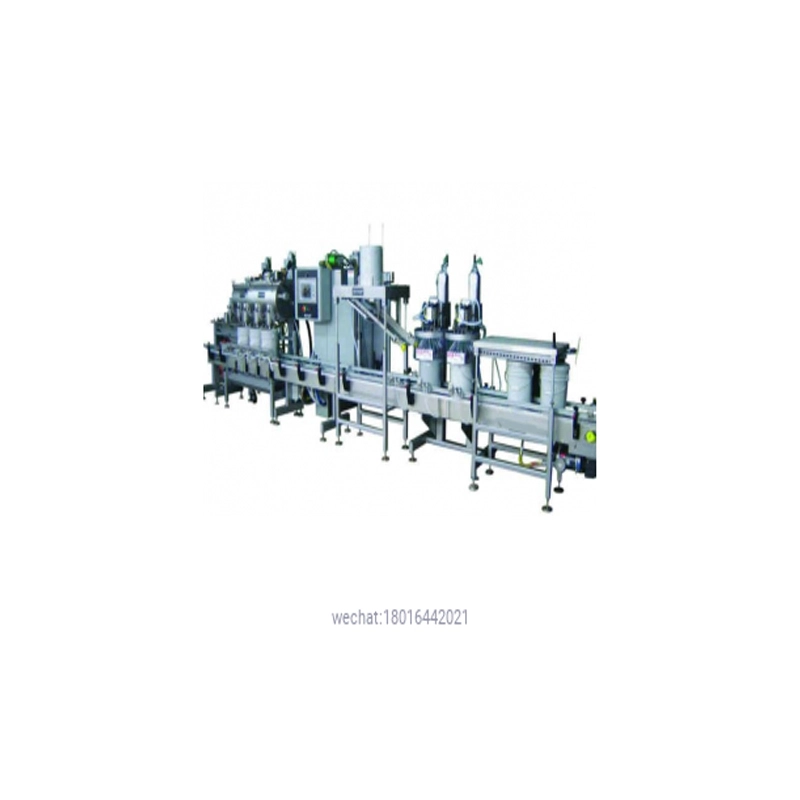

3 – Head Automatic Net Weight Filling <000000> Crimp Closing Machine for Gallon to Pail Containers with POP Fill Cart

This innovative machine offers precise net weight filling and secure crimp closing for gallon to pail containers, complete with a convenient POP fill cart. The 3-head design ensures efficient and accurate operation, perfect for streamlining your packaging process.

Main features

Three Head Automatic Net Weight Liquid Filling Machine delivers the highest levels of automation and precision filling performance in a full-featured package.

Automatic PLC-controlled filling, lid placement, crimp lid closing and conveyor systems for hands-free operation.

Choice of Pressure Over Product (POP) or Manifold-based Fill Carts.

Containers: Gallon to Pails.

APPLICABLE BARREL TYPE

COMPANY PROFILE

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

Detalhes do produto

We will ensure that our company's equipment has safety, stability, high efficiency and intelli.gent technology, so as to meet your needs, we can also cooperate with you in selecting in-ternationalproduct brand production and business.

Live Shooting

Support customization, low price, no middlemen, factory direct sales, large quantity and more favorable. Product quality assurance, simple operation and durability. We have professional customer service to consult and provide technical guidance at any time.

Company Certificate

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance

This is a partial service for us in China.

Over 30 years of experience, every time we produce in Shanghai, our friends can visit our factory at any time.

Brand components

We will ensure that our company's equipment has safety, stability, high efficiency and intelli-gent technology, so as to meet your needs, we can also cooperate with you in selecting in-ternational product brand production and business.

Our service

packge and delivery

Multiple Transportation way :Express(Fedex/DHL/TNT/EMS/UPS etc),air and shipping for your choose

FAQs

Nossos designers e engenheiros internos produziram inúmeros designs excelentes para clientes de diferentes setores