Filling Systems Fully Automaticsupplier

Efficient, Reliable, Precise Dispensing

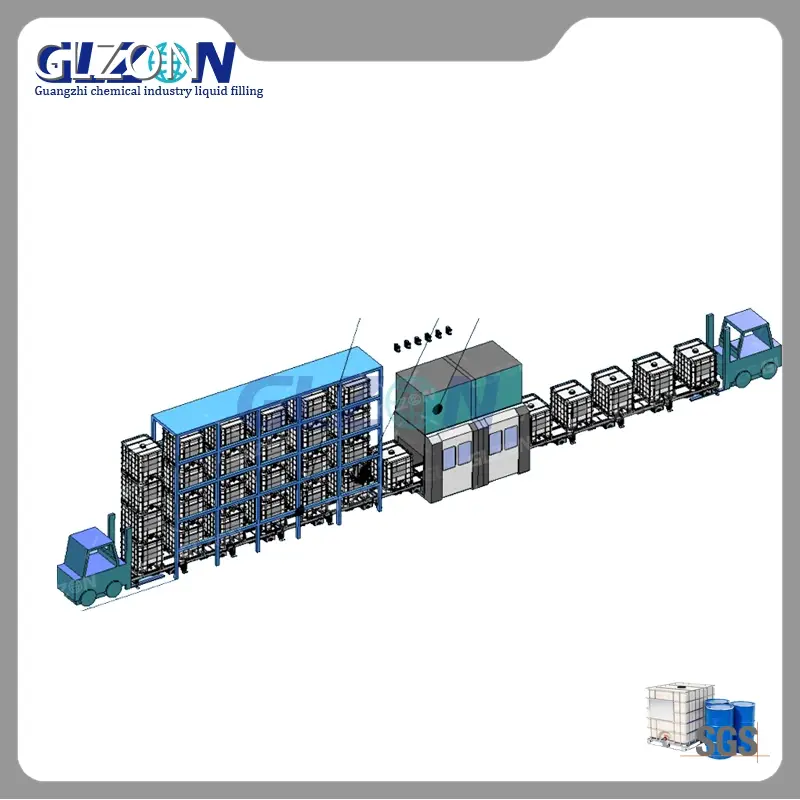

Upgrade your chemical industry operations with our Factory Direct Supply CNC Dispensing Polyurethane Filling Machine that's accurate, efficient, and saves costs. Our pallet IBC filling machine is suitable for a range of liquid materials and features an automatic filling gun for reliable operation. With 12 months of trouble-free warranty and reliable after-sales service, we are here to provide you with high-quality machinery and support for your operations.

Product Display

Efficient, Precise, Safe, Reliable

Precise Industrial Polyurethane Filling

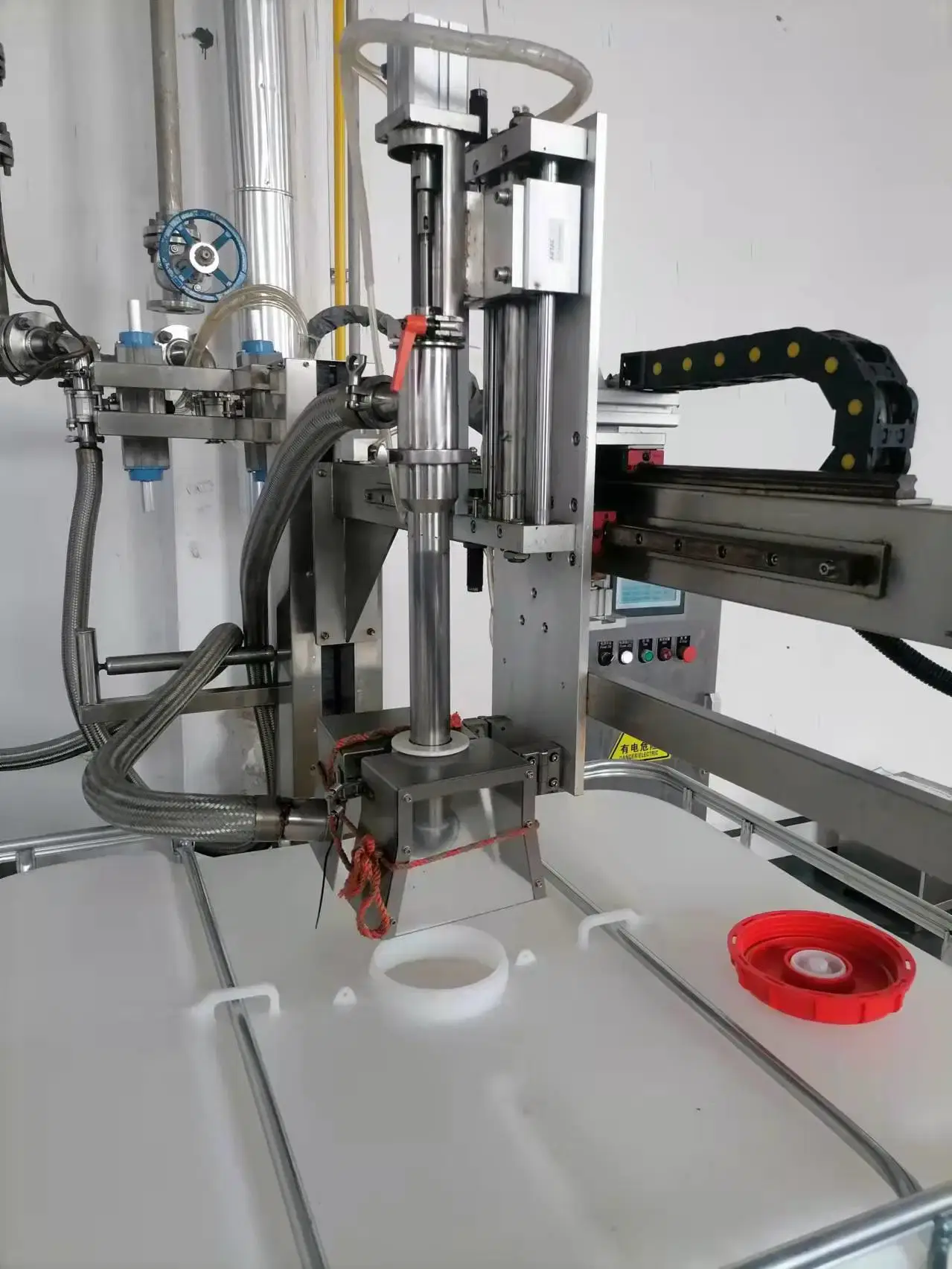

The Factory Direct Supply CNC Dispensing Polyurethane Filling Machine is ideal for the chemical industry, as it is equipped to fill large IBC barrels and 200kg four-barrel barrels. Programmable PLC controllers enable reliable barrel conveying and discharging, and the automatic rotation of the filling head makes for efficient operation. With features such as an integral technology filling gun to prevent dripping, quick-release connectors, and an adjustable filling gun height, this machine is designed for safety, ease of use, and flexibility, making it suitable for rapid filling of packaging barrels of various specifications. The product also boasts a large and small ball width group, a double-stage filling gun, and system target value settings, offering high accuracy in filling and an efficient one-click operation.

Application Scenario

Material Introduction

The Factory Direct CNC Dispensing Polyurethane Filling Machine is designed to streamline the filling process, ensuring accurate and efficient production in the chemical industry. With a capacity of 200-1000KG and an accuracy of 0.2%, this machine offers reliable and precise filling for liquid materials such as coating, paint, asphalt, and more. Equipped with cutting-edge technology and built-in safety features to prevent dripping and splashing, this machine provides a user-friendly, cost-effective solution for the packaging and filling of chemicals, improving operational efficiency and reducing manual operation pressure. With brand components and top-notch engineering, Shanghai Guangzhi Automation Equipment Co., Ltd. delivers a high-tech, reliable product backed by a comprehensive pre and post-sale service, setting a new standard in industry technology and innovation.

FAQ

Company Advantages

· GLZON filling systems is precisely measured and tested to ensure an extremely precise specification.

· The implementation of the complete quality management system greatly guarantee that the product is manufactured according to the international quality standards.

· Shanghai Glzon Equipment Co., Ltd continuously creates good results in the field of filling systems.

Company Features

· Over years of development, Shanghai Glzon Equipment Co., Ltd has gained extensive expertise in manufacturing filling systems and has been a reliable manufacturer in the industry.

· All GLZON products have passed the relevant international standards certification.

· GLZON will always stick to its strategic focus and make every effort to support the production of filling systems.

Application of the Product

filling systems of GLZON can play a role in various industries.

According to different needs of customers, GLZON is capable of providing reasonable, comprehensive and the most cost-effective solutions for customers.