Semi Automatic Capsule Filling Machine Manufacturer Provided

Product details of the semi automatic capsule filling machine

Product Specification

Filling Accuracy: 0.2%

Core Components: Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

Video outgoing-inspection.: Provided

After-sales Service Provided.: Video technical support, Online support

Application: Food, Beverage, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, Cigarettes, Tobacco, Cosmetic, Water, Other

Quick Detail

GLZON semi automatic capsule filling machine is endowed with exceptional appearance. Its beautiful design comes from our exclusive designers with strong innovation and design capabilities. The product is completely examined by the quality testing department. Shanghai Glzon Equipment Co., Ltd uses international capital markets to accelerate development in semi automatic capsule filling machine field.

Product Information

Compared with other products in the same category, semi automatic capsule filling machine produced by GLZON has the following advantages.

Efficient and Accurate Chemical Filling

Our Semi-automatic Multi-head Chemical Liquid Weighing Drum Filling Machine and Filling Equipment is designed to provide precise and efficient filling for a variety of liquid materials such as coating, printing ink, paint, and petrochemicals. With a filling capacity of 30-200KG and an accuracy of 0.20%, our machine ensures reliable and consistent results. Additionally, our company offers professional packaging and logistic services, pre-sale testing, and after-sale support to ensure a seamless experience for our customers.

Product Display

Efficient, Precise, Versatile, Automated

Efficient, Accurate, Versatile Filling Technology

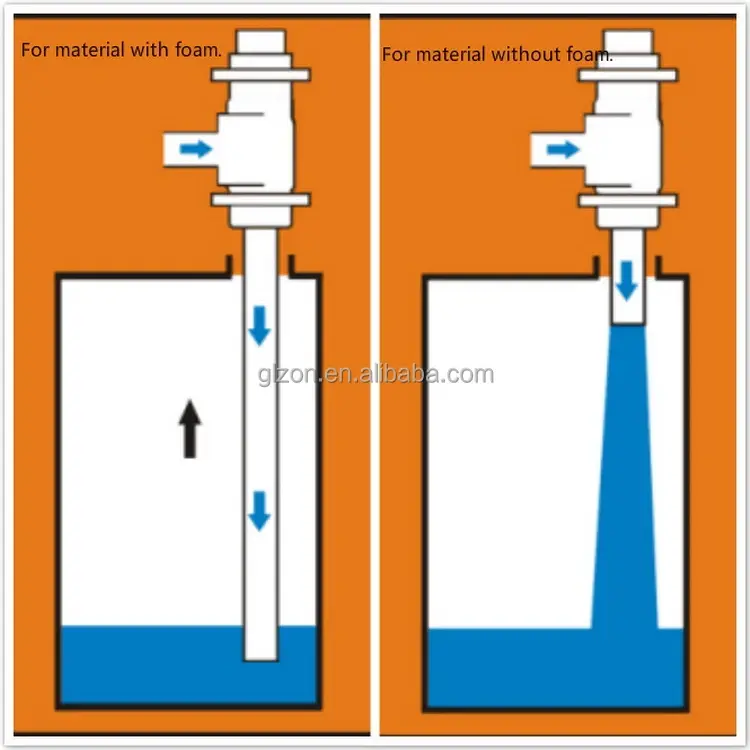

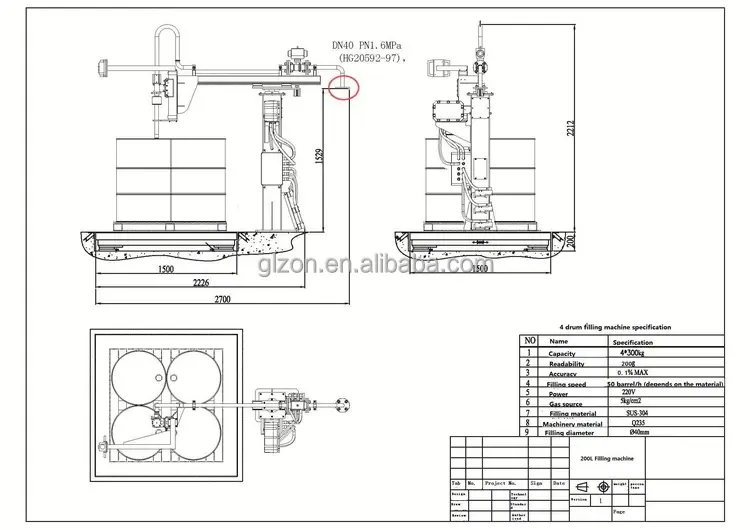

The Semi-automatic Multi-head Chemical Liquid Weighing Drum Filling Machine And Filling Equipment (Model GZM-200-2PT) is designed for filling liquid materials such as coating, printing ink, paint, asphalt, glue, lubricant, and petrochemicals with a weighing capacity of 30-200KG and an accuracy of 0.20%. It is equipped with two filling stations, capable of filling above level (liquid without foam) and below level (liquid with foam) at a speed of 60-120 containers per hour. The machine is constructed with high-quality materials such as SUS304, SUS316, and PTFE, and offers an optional Ex-Proof model for hazardous environments, making it suitable for a wide range of industrial applications.

Application Scenario

Material Introduction

Our semi-automatic multi-head chemical liquid weighing drum filling machine and filling equipment, Model GZM-200-2PT, is designed to accurately and efficiently fill a wide range of liquid materials, such as coating, printing ink, paint, asphalt, glue, lubricant, petrochemical, and fine chemical products. With a filling capacity of 30-200KG and an accuracy of 0.20%, this machine offers a filling speed of 60-120 containers per hour, maximizing productivity for users. Additionally, our machine is designed for versatility, being able to fill various types of containers including pails, cans, bottles, tins, drums, and IBCs, providing users with a flexible and efficient solution for their liquid filling needs.

FAQ

Company Introduction

Shanghai Glzon Equipment Co., Ltd is a professional company dedicated to R&D and production of Drum Filling Machine,Pallet And Ibc Filling Machine,Jerry Can Filling Machine,Canister Filling Ma. We are currently located in shang hai. GLZON adheres to the 'customer first' principle to provide quality services for customers. Welcome customers and friends who are in need to contact us and look forward to reaching a friendly cooperation with you!