Product details of the empty can depalletizer

Product Specification

Packaging Material: Metal

Barrel Form: Pail, Can, Bottle, Drum, IBC etc.

Filling speed: 60-120barrels/Hour(200L)

Filling Mouth Material: SUS304/SUS316/PTFE

Product Information

GLZON empty can depalletizer is design based on industry-leading design concept. In the production process, advanced testing equipment is used to test the products to ensure the high performance and consistency of the products. Shanghai Glzon Equipment Co., Ltd has accumulated experience and advantages in empty can depalletizer field.

Efficient, Safe, Precise Filling

Experience the convenience of the Fully Automatic Inline Ex-Proof Ferrite Thinner 200L Drum Filler, a weighing and filling machine, which offers efficient and fast barrel filling. With the ability to set the filling system targets freely and the option for explosive proof, you can ensure safe, accurate, and fast filling for all your liquid products. Produced by Shanghai Guangzhi Automation Equipment Co., Ltd, this machine is designed to improve your operational efficiency and reduce losses, making it a valuable investment for your industrial needs.

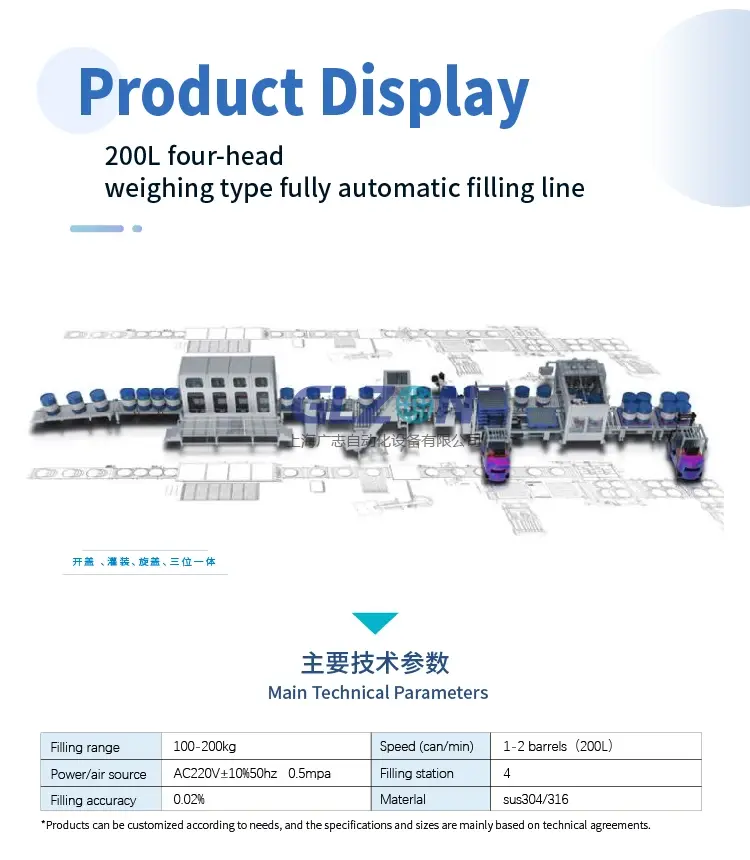

Product Display

Efficient, Safe, Precise, Versatile

Efficient, Safe, Precise Filling

The Fully Automatic Inline Ex-Proof Ferrite Thinner 200L Drum Filler is a highly advanced China weighing filling machine designed to fill 200kg barrels with liquid, such as coating, printing ink, paint, and more with an accuracy of 0.2% and a speed of 60-120 barrels per hour. Equipped with a large and small ball width group and a double-stage filling gun, the system can be operated with one-click and provides real-time display and automatic alarms for deviation. With a focus on industrial digital services, Shanghai Guangzhi Automation Equipment Co., Ltd. has over 10 years of experience and offers professional packaging and logistic services, pre-sale and after-sale service, and free training courses to technicians.

Application Scenario

Material Introduction

Experience the convenience and efficiency of the Fully Automatic Inline Ex-Proof Ferrite Thinner 200L Drum Filler, a state-of-the-art weighing and filling machine. This machine provides precise and accurate filling, with a filling capacity of 100-200KG and an accuracy of 0.2%. The intelligent control system, quick-release connector, and easy operation make this machine an essential addition to any industrial setting, promoting cost savings, improved efficiency, and reduced manual operation pressure for users.

FAQ

Company Feature

• Our company insists on combining standardized services with personalized services to meet the different service needs of customers. It contributes to the brand image building of our company's quality service.

• With a focus on talents development, GLZON has a talent team mainly engaged in scientific research. They provide technical support for us to develop and innovate our products.

• GLZON's location enjoys a comprehensive traffic network, which is good for the distribution of products.

• GLZON's Drum Filling Machine,Pallet And Ibc Filling Machine,Jerry Can Filling Machine,Canister Filling Ma are supplied throughout the country. They are also exported to some countries and regions like br /> GLZON is greatly motivated by your inquiries and suggestions!