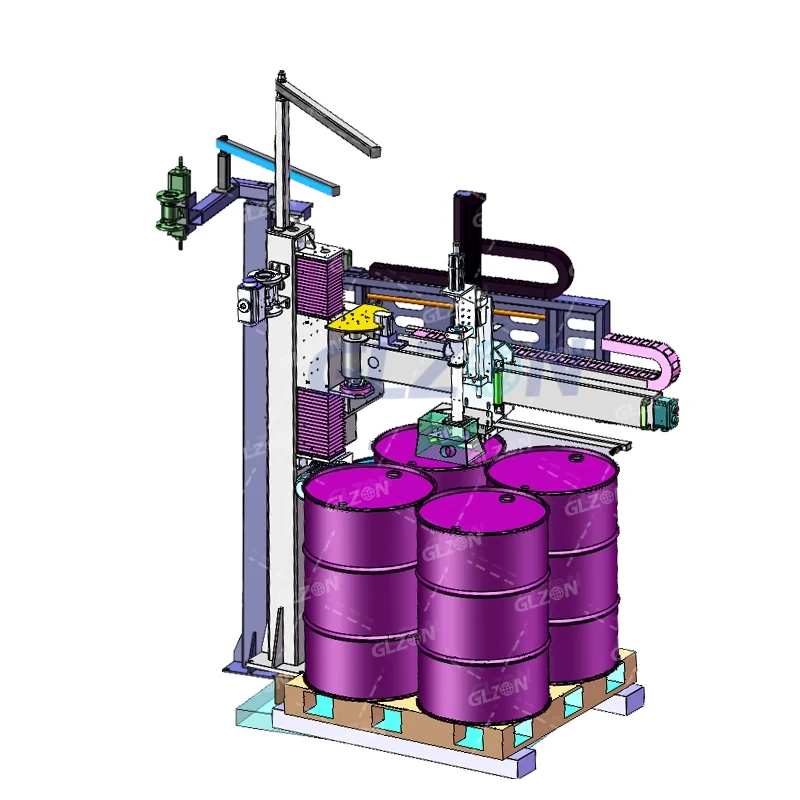

Semi-automatic Ex-proof Slurry Swing Arm Drum Filling Machine

Efficient, Safe, Versatile Filling Solution

Choose our Semi-automatic Ex-proof Slurry Swing Arm Type 4*200l Drum Filling Machine for accurate and efficient filling of liquid products such as coating, ink, paint, asphalt, and more. With a filling capacity of 200-1000KG and an accuracy of 0.2%, this machine offers a fast filling speed of 60-120 drum/Hour (200L) for various barrel forms. Our company, Shanghai Guangzhi Automation Equipment Co., Ltd., provides professional packaging solutions, pre-sale service, and after-sale support, ensuring a seamless experience for our customers.

Product Display

Efficient, Safe, Precise, Durable

Efficient, Safe, Precise, Automated Drum Filling

The GZM-1000-4PT is a semi-automatic ex-proof slurry swing arm type 4*200l drum filling machine suitable for filling liquids such as coating, printing ink, paint, asphalt, glue, and petrochemicals. It has a filling capacity of 200-1000KG with an accuracy of 0.2%, and a filling speed of 60-120 drums per hour (200L). The machine comes with various high-quality components from well-known brands such as Siemens, Mettler-Toledo, and ABB, and is designed to improve efficiency in the food, chemical, and pharmaceutical industries. With a complete intelligent control system, it offers professional packaging and logistic services, pre-sale support, and after-sales service including free parts and low-cost maintenance.

Application Scenario

Material Introduction

The Semi-automatic Ex-proof Slurry Swing Arm Type 4*200l Drum Filling Machine by Shanghai Guangzhi Automation Equipment Co., Ltd. is a high-tech solution for the digital industrialization of liquid pumping machinery. With a filling capacity of 200-1000KG and an accuracy of 0.2%, this machine is suitable for filling a wide range of liquids such as coating, printing ink, paint, asphalt, glue, lubricant, petrochemical, and fine chemical products. Equipped with top-quality components from Siemens, Kunlun Tongtai, Mettler-Toledo, and ABB, this machine guarantees precision, efficiency, and reliability. With professional packaging and logistic services, pre-sale assistance, and after-sale support, choosing this product ensures a seamless and comprehensive solution for your liquid filling needs.

FAQ