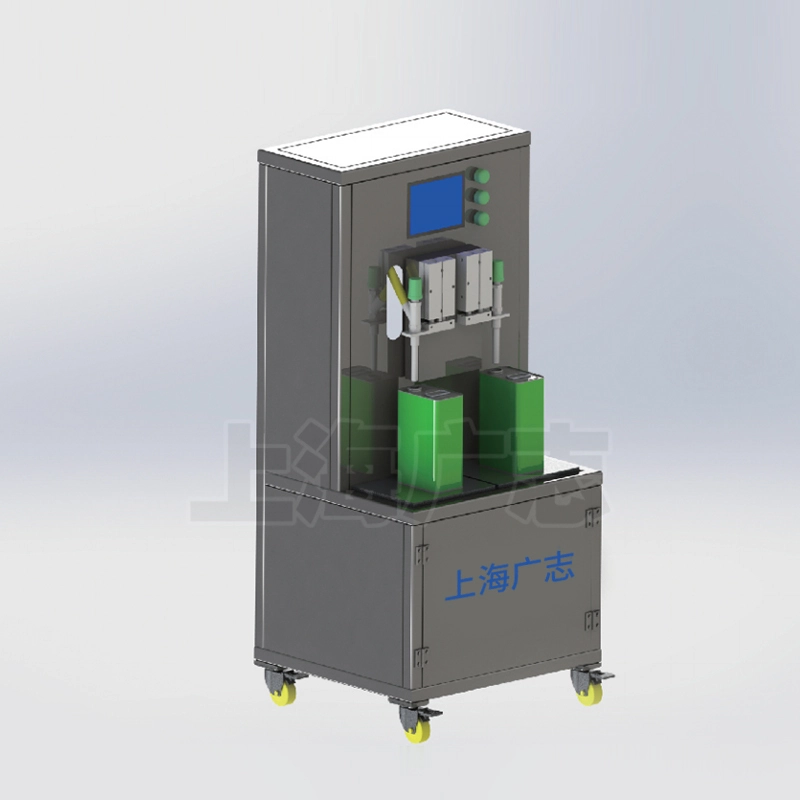

Tin can filling machine

1. This filling machine is an automatic device for filling all types of liquids and viscous products. It is the best solution for tins, canisters and pails from 1 to 30 liters. The device stands out for its versatility and does not require installation, so you can start production from the beginning. The interface design is designed for operators and is very easy to use.

2. Suitable for filling small-mouth barrels within 60kg, the system adopts programmable PLC control, full English guidance, easy operation; manual barreling, automatic filling. Equipped with automatic capping machine, automatic palletizer.

3. There are two filling methods: bottom filling and top filling:

Bottom filling is suitable for flowable liquids that are easy to foam and generate static electricity. The filling head extends into the bottom of the barrel and moves upward while filling.

Top filling is filling on the liquid surface in the barrel, suitable for filling non-foaming liquids. The filling head is inserted into the barrel mouth and automatically returns if it is not aligned.

Main features:

1. This filling machine is an automatic device for filling all types of liquids and viscous products. It is the best solution for tins, canisters and pails from 1 to 30 liters. The device stands out for its versatility and does not require installation, so you can start production from the beginning. The interface design is designed for operators and is very easy to use.

2. Suitable for filling small-mouth barrels within 60kg, the system adopts programmable PLC control, full English guidance, easy operation; manual barreling, automatic filling. Equipped with automatic capping machine, automatic palletizer.

3. There are two filling methods: bottom filling and top filling:

Bottom filling is suitable for flowable liquids that are easy to foam and generate static electricity. The filling head extends into the bottom of the barrel and moves upward while filling.

Top filling is filling on the liquid surface in the barrel, suitable for filling non-foaming liquids. The filling head is inserted into the barrel mouth and automatically returns if it is not aligned.

| Containers |

Tin can /square Tin plate cans |

| Filling head | double head (single head can be customized) |

| Capacity | 0.5~10L (kg) |

| Power supply | AC380V±10% 50HZ |

| Production | 250~300 containers/hour |

| Air source | 0.5MPA |

| Filling precision | ±0.1% |

| Explosion-proof grade | ExdIIBT4 |

| Explosion-proof grade |

non-explosion-proof (explosion-proof can be customized) |

| Applicable materials | curing agent, ink, resin, pesticide, daily chemical, edible oil and other industries |