Automatic Drum Filling Machines: Features And Benefits

Are you looking for a more efficient and cost-effective solution for filling drums in your manufacturing facility? Look no further! Our article on automatic drum filling machines dives into the features and benefits of this innovative equipment. From increased productivity to improved safety measures, these machines offer a range of advantages that can transform your filling process. Read on to discover how automatic drum filling machines can revolutionize your operation.

Automatic Drum Filling Machines: Features and Benefits

In today's fast-paced manufacturing world, efficiency and accuracy are key considerations. Whether you are in the chemical, food, pharmaceutical, or any other industry that requires the filling of drums, investing in an automatic drum filling machine can greatly improve your production process. In this article, we will explore the features and benefits of automatic drum filling machines and how they can enhance your business operations.

I. Understanding Automatic Drum Filling Machines

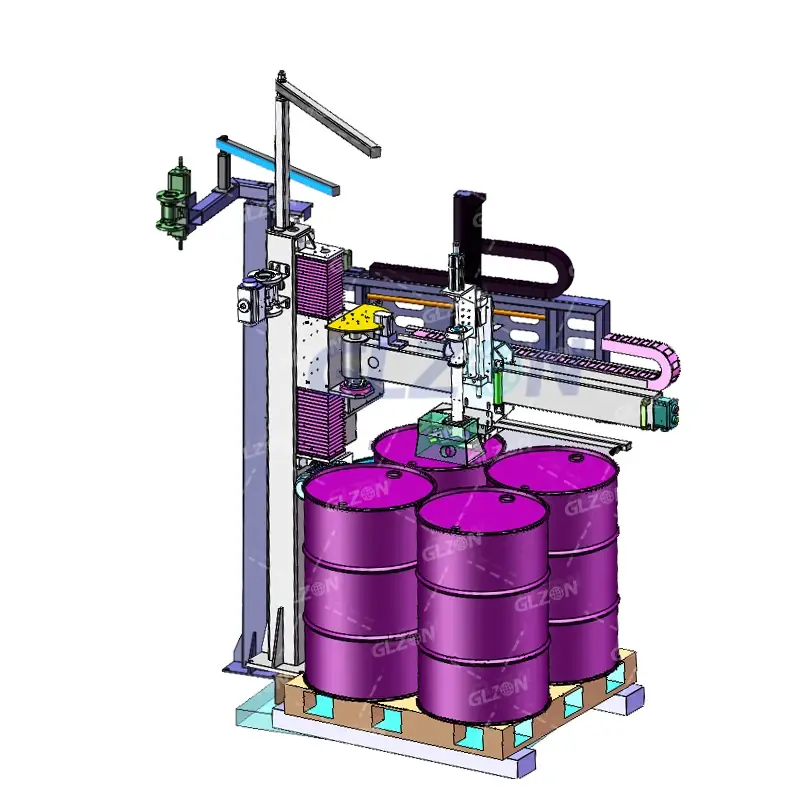

Automatic drum filling machines are designed to precisely fill drums with liquid or powdered substances. These machines are equipped with advanced technology that allows for automated filling, minimizing human error and increasing production output. Different models of automatic drum filling machines are available on the market, ranging from semi-automatic to fully automatic, with various features and capabilities to suit different production needs.

II. Features of Automatic Drum Filling Machines

One of the key features of automatic drum filling machines is their precision and accuracy. These machines are programmed to dispense the exact amount of product into each drum, ensuring uniform filling and minimizing product waste. Additionally, many automatic drum filling machines are equipped with advanced control systems and sensors that monitor the filling process in real-time, allowing for adjustments to be made on the fly to maintain consistency.

Another important feature of automatic drum filling machines is their versatility. These machines can handle a wide range of drum sizes and types, from steel and plastic drums to various capacities. They can also accommodate different types of products, including viscous liquids, corrosive chemicals, and powders, making them suitable for a variety of industries.

Furthermore, automatic drum filling machines are designed for ease of use and maintenance. They are built with user-friendly interfaces and are often equipped with self-cleaning mechanisms, reducing downtime for cleaning and maintenance.

III. Benefits of Automatic Drum Filling Machines

Investing in an automatic drum filling machine offers numerous benefits for businesses. Firstly, these machines significantly increase productivity and efficiency by automating the filling process. This allows employees to focus on other tasks, leading to overall improved workflow and operational efficiency.

Additionally, automatic drum filling machines reduce the risk of product contamination and human error, resulting in higher product quality and consistency. This is especially crucial for industries with stringent quality control requirements, such as pharmaceuticals and food production.

Moreover, automatic drum filling machines help businesses save on labor costs and minimize product waste, leading to cost savings in the long run. By accurately dispensing the exact amount of product into each drum, businesses can maximize their resources and improve their bottom line.

IV. Why Choose GLZON Automatic Drum Filling Machines?

At GLZON, we pride ourselves on providing high-quality automatic drum filling machines that are designed to meet the diverse needs of our customers. Our machines are engineered with cutting-edge technology, ensuring precision and reliability in every filling operation.

Our automatic drum filling machines are equipped with customizable features and controls, allowing businesses to tailor the machines to their specific production requirements. Whether you need to fill a wide range of drum sizes or handle different types of products, our machines are versatile enough to accommodate your needs.

Furthermore, our automatic drum filling machines are designed for easy integration into existing production lines, minimizing downtime and disruptions to your operations. With our commitment to customer satisfaction, we offer comprehensive after-sales support and maintenance services to ensure the long-term performance and reliability of our machines.

V.

In conclusion, automatic drum filling machines offer a range of features and benefits that can significantly enhance the production process for businesses across various industries. From precision and accuracy to versatility and efficiency, these machines are a valuable investment for any business looking to streamline their filling operations.

If you are considering investing in an automatic drum filling machine, look no further than GLZON. With our commitment to quality and customer satisfaction, we provide innovative and reliable solutions to meet your specific production needs. Contact us today to learn more about our automatic drum filling machines and how they can benefit your business.

Conclusion

In conclusion, automatic drum filling machines offer a wide range of features and benefits that can greatly improve the efficiency and productivity of any manufacturing or packaging facility. From precise filling accuracy to streamlined operation and increased safety, these machines are a valuable investment for any company. With 22 years of experience in the industry, we understand the importance of high-quality equipment and are committed to providing the best automatic drum filling machines to meet the needs of our clients. Whether you are looking to increase output, improve accuracy, or enhance safety, our automatic drum filling machines are the ideal solution for your business. Thank you for considering our products, and we look forward to continuing to serve you in the future.